- Home

- Vision System

- Vision System

Vision System

For The Best Quality Inspection

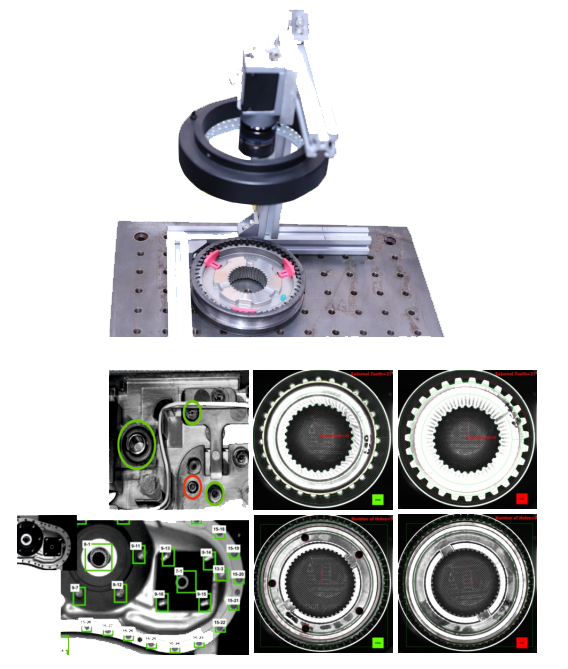

A machine vision system integrates cameras, image processing software, and hardware to enable visual perception for various industrial applications. This technology plays a crucial role in tasks like quality control, inspection, measurement, and automation across diverse industries.

Key Components of a Machine Vision System:

- Cameras: Captures high-resolution visual information which is fundamental for collecting data from inspected objects.

- Illumination: Provides proper lighting for clear image capture which enhances visibility, highlighting specific features for analysis.

- Lens: Focuses light onto the camera sensor, influencing factors like field of view, used for determining optical characteristics for varied applications.

- Vision Processor: System’s cognitive center for image processing and analysis,which executes algorithms, interprets visual data, and makes decisions based on predefined criteria.

- Communication Interface: Facilitates communication with other machines or systems which enables seamless integration into larger automated processes.

- Software: Employs algorithms for image processing, pattern recognition, and decision-making hence allowing customization based on specific application requirements.

A well-integrated machine vision system relies on these components working in harmony, providing accurate and efficient visual perception for quality control, inspection, and automation in diverse industries.

Key Functions of Machine Vision Systems:

- Inspection and Quality Control: Ensures that products meet quality standards by detecting defects which is critical in manufacturing, electronics, and automotive industries.

- Measurement and Dimensional Analysis: Provides precise measurements, verifying dimensional accuracy.which is crucial for maintaining manufacturing process standards.

- Identification and Recognition: Identifies objects, patterns, codes, or text for tracking and authentication..

- Guidance and Alignment: Guides robotic systems or aligns components accurately during assembly which is essential in ensuring precise assembly processes in manufacturing.

- Sorting and Classification: Efficiently sorts or classifies objects based on visual characteristics and hence enhances material handling and distribution in logistics and production.

- OCR (Optical Character Recognition): Reads and interprets text, valuable for tasks like reading barcodes or product labels which is essential for accurate data retrieval and tracking.

- Defect Detection: Identifies and flags defects or irregularities in products and therefore helps in eliminating faulty items from the production line, maintaining quality standards.

Advantages of Machine Vision Systems:

- Accuracy and Precision: High accuracy and precision in visual inspection, minimizing human error.

- Speed and Efficiency: Rapid image processing for quick analysis, enhancing overall process efficiency.

- Consistency: Ensures consistent performance, maintaining uniformity in inspection and quality control.

- Non-Contact Inspection: Minimizes the risk of damage to delicate or sensitive objects during inspection.

- 24/7 Operation: Enables continuous, round-the-clock inspection and monitoring in industrial settings.

Machine vision systems utilize cutting-edge technologies to automate visual inspection and analysis tasks, offering a reliable and efficient solution across diverse industrial applications.