- Home

- Semi Automatic Welding

- Semi Automatic Welding

Semi Automatic Welding

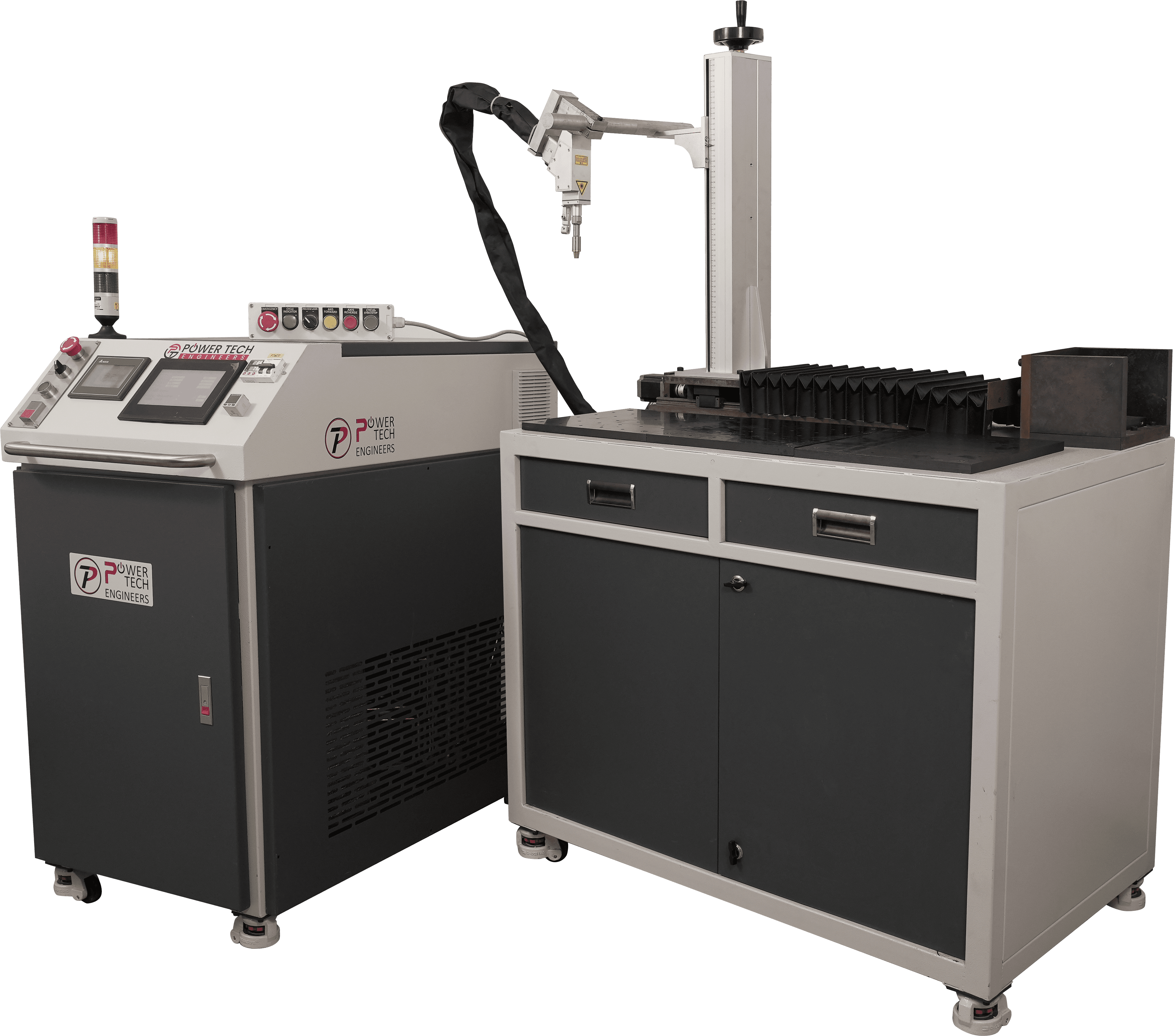

For Effortless Precision: Revolutionize Welding with Our Semi-Automatic Marvel!

Introducing our cutting-edge semi-automatic welding machine – where precision meets efficiency! Designed for seamless welding experiences, this state-of-the-art machine combines the ease of automation with the skill of manual control. Designed for versatility and ease of use, this cutting-edge machine empowers welders to achieve impeccable welds with precision and speed. Whether you’re a seasoned professional or a novice, our semi-automatic welding machine ensures a seamless welding experience, making your projects a masterpiece. Elevate your welding game with the perfect blend of automation and craftsmanship.

Semi Automatic Laser Welding Machine has advantages over manual welding

- Increased Efficiency: It enhances productivity by automating repetitive tasks, allowing operators to focus on precise welding control.

- Consistent Quality: It ensures consistent weld quality through steady speed and electrode placement, mitigating challenges associated with human factors like fatigue and skill variability in manual welding.

- Reduced Operator Fatigue: It minimizes operator physical strain, enhancing comfort, reducing fatigue, and improving concentration for heightened job satisfaction.

- Cost Savings: It offers cost savings by boosting productivity and diminishing the reliance on highly skilled welders, presenting a cost-effective solution for diverse welding applications.

Semi Automatic Laser Welding Machine has advantages over robotic welding

- Flexibility and Adaptability: It offers superior flexibility, easily adapting to diverse welding tasks and proving more suitable for small batch production or applications requiring frequent changes in welding parameters compared to robotic systems.

- Lower Initial Investment: Their lower initial costs as compared to fully automated robotic systems, provides more accessible option for smaller businesses or those with budget constraints.

- Ease of Programming and Operation: It offers simpler programming and operation while facilitating rapid learning and deployment by operators of varying expertise.

- Space Requirements: It requires less floor space than robotic cells, offering an advantage in environments with space constraints or frequent workspace reconfiguration needs.

In summary, Semi-automatic welding machines provide a balanced solution, combining the precision and efficiency of automation with the flexibility of manual welding, finding application in scenarios requiring a middle-ground approach and offering advantages over both manual and robotic welding systems in specific contexts